Sanitary Standards

Sanitary Standards

3-A Sanitary Standards, Inc. was incorporated as an independent not-for-profit corporation in 2002 dedicated to the mission of advancing food safety through hygienic equipment design. The membership consists of four associations: American Dairy Products Institute, International Dairy Foods Association, Food Processing Suppliers Association and the International Association for Food Protection.

Today’s 3-A SSI maintains a large inventory of design criteria for equipment and processing systems developed using a modern consensus process based on ANSI requirements to promote acceptance by USDA, FDA and state regulatory authorities. 3-A SSI oversees the 3-A Symbol Authorization program and other voluntary certificates to help affirm the integrity of hygienic processing equipment and systems.

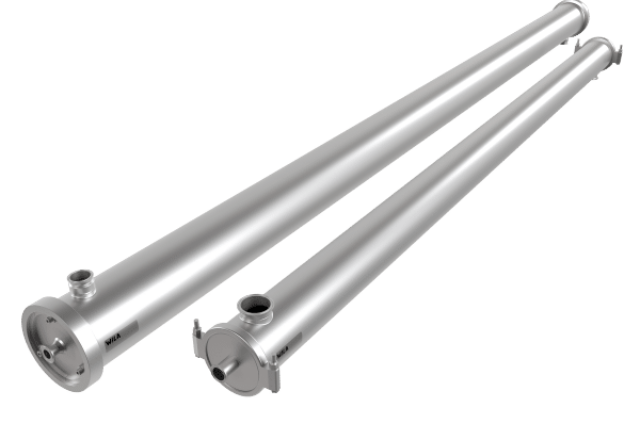

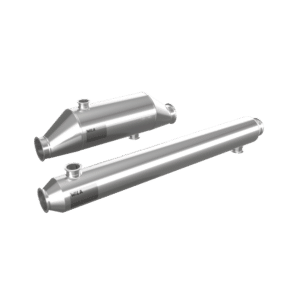

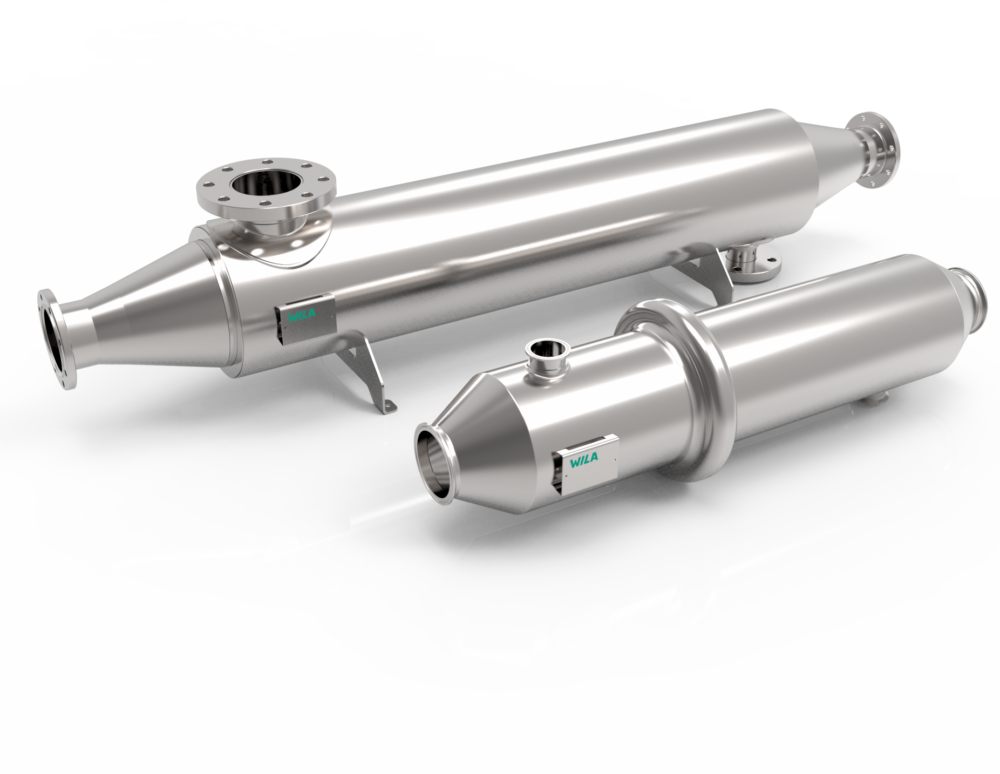

At Wila, we have a range of Tubular Heat Exchangers, which are 3A certified. Our 3A certified products include THEA – TLCA – THEXA – TLCXA – TSHA – TSHXA – TEFA – DEFA.

Don’t hesitate to contact our sales department for more information.

Tubular heat exchangers are highly used in the food and beverage industry and in connection with many applications, such as CIP units. In the food and beverage industry, tubular heat exchangers are often used in systems to reduce or eliminate microbials to make products safe for consumption and extend their shelf life. A tubular heat exchanger may also be used to heat or cool products prior to filling, drying, concentration, or other processes.

Tubular heat exchangers are highly used in the food and beverage industry and in connection with many applications, such as CIP units. In the food and beverage industry, tubular heat exchangers are often used in systems to reduce or eliminate microbials to make products safe for consumption and extend their shelf life. A tubular heat exchanger may also be used to heat or cool products prior to filling, drying, concentration, or other processes.

Sanitary Standards

Sanitary Standards