Beverage industry

Beverages based on natural products such as fruit and vegetable juices have become very popular. The industry has reacted to the increasing demand by producing a wide variety of products that make our drinks shelves look very colourful. Not every product needs to be organic, but they are all expected to be healthy and tasty.

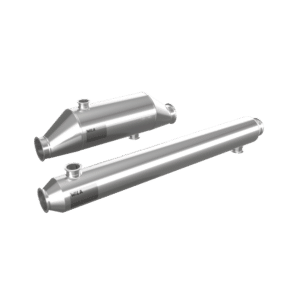

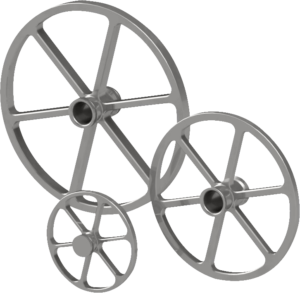

Heat exchangers for beverage processing, much like diary processing, are focused on the pasteurization of products. Juices require pasteurization for the sterilization of the juices for consumption. The challenge of designing a heat transfer system for juices is the careful process needed to retain the natural qualities of the beverage. Ensuring that taste, colour and nutrients are retained, post heat transfer is vital to modern beverage production. The ability to meet expected quality levels requires production process and final product expertise. Wila is well positioned to meet these end customer requirements. We supply equipment and technologies for the fruit and vegetable juice industry. As a supplier of complete lines, our experienced engineers will work with you to develop an innovative and efficient process which can meet your specific needs.

Wila’s experience in this market means that we have a key understanding of the entire production process and can meet your needs. We can tailor and optimize our solutions to your requirements, whether for a completely new plant or a single heat exchanger or membrane housing.

“At Wila A/S, we have a dedicated and skilled staff who perform all tasks with common sense, great professionalism, pride and expertise.”